Galvanized Aluminum-Zinc steel sheet

Key words:

Galvanized Aluminum-Zinc steel sheet

Classification:

- Details

Product Overview

Galvanized aluminum-zinc-silicon plates are primarily used in construction, light industry, automotive, agriculture, animal husbandry, fisheries, and commercial and civilian electronics industries. In the construction industry, they are used to make corrosion-resistant industrial and civil building roof panels and roof grilles; in the light industry, they are used to manufacture household appliance shells, civil chimneys, kitchen utensils; in the automotive industry, they are used to make corrosion-resistant parts for cars; in agriculture, forestry, and fisheries, they are used for grain storage, meat, and aquatic product freezing equipment; in commerce, they are used for commodity storage and packaging tools; in civilian electronics, they are used to manufacture solar heat collectors.

Product Specification

| Items | Index |

| Annual design capacity | 200,000 tons |

| Thickness | 0.15~0.8mm |

| Width | 800~1250mm |

| Product unit weight | ≤100 Tons |

| Product inner diameter | Φ508 |

| Zinc flower state | large and small zinc flowers |

| Surface Treatment | common passivation; colorless fingerprint-resistant passivation; colored fingerprint-resistant passivation; chromium-free fingerprint-resistant passivation; oiling |

| Process | 55% aluminum, 43.5% zinc, 1.5% silicon, full radiation reduction method |

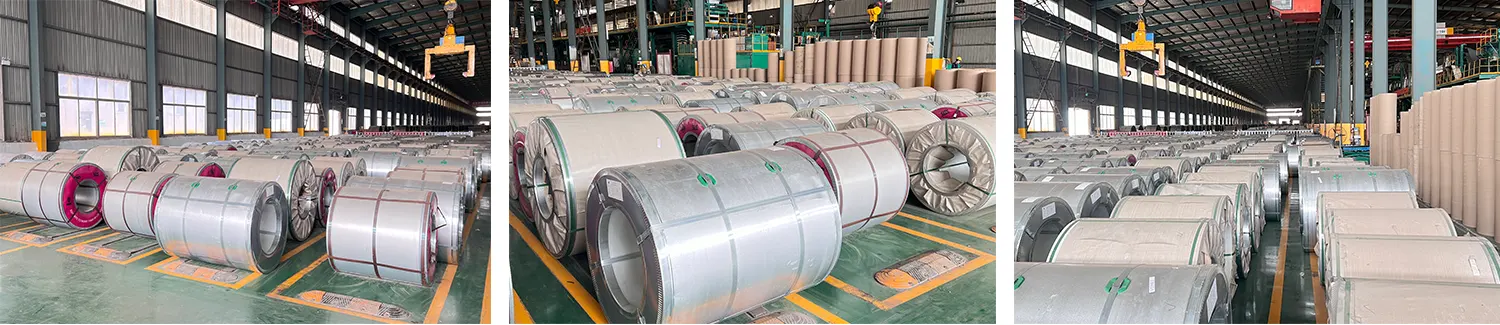

Galvanized Aluminum-Zinc-Silicon Production Line

In October 2016, the company put into operation a new galvanized aluminum-zinc-silicon production line with an annual output of 200,000 tons. The product thickness ranges from 0.15mm to 0.8mm, and width from 800mm to 1250mm, with a zinc coating thickness from 30g/m² to 150g/m². The product surface is smooth, with strong three-dimensionality and excellent atmospheric corrosion resistance, approximately 2 to 6 times higher than that of similarly hot-dipped galvanized plates.

Production Strength

In 2020, the company built four new intelligent rolling production lines with an annual output of 1 million tons of high-precision steel plates, one continuous intelligent pickling production line with an annual output of 800,000 tons, and one 8㎡/h environmentally friendly acid regeneration production line. Additionally, the company boasts one galvanized steel production line with an annual output of 250,000 tons, one color-coating steel production line with an annual output of 150,000 tons, and two continuous intelligent pickling production lines with annual outputs of 800,000 tons and 600,000 tons, respectively. By 2023, the company had five 1150 rolling mills with an annual output of 200,000 tons and two 1380 rolling mills with an annual output of 250,000 tons, ensuring the supply of high-quality raw materials required for galvanized steel and color-coated steel production, successfully realizing the high-precision and specialized production of enterprise products and promoting the construction process of the company's core competitiveness.

Packaging and shipping

Domestic sales and international trade are carried out simultaneously, with products exported to all corners of the world. Clients and partners are located in regions and countries such as Africa, the Middle East, Europe, Japan, and South Korea, and have received widespread praise and trust from customers. The company will actively respond to future fierce competition, achieve diversified operations, create a strong and vibrant Huayun brand, and realize brand expansion and leapfrog development of enterprise scale.

Applications

The main supply fields include: aerospace, chemical industry, shipbuilding, nuclear energy, trains, environmental protection, precision machining, automotive parts, machinery, electronic products, molds and dies, medical equipment, construction, decoration and so on.

Get free product quotes

Related Products